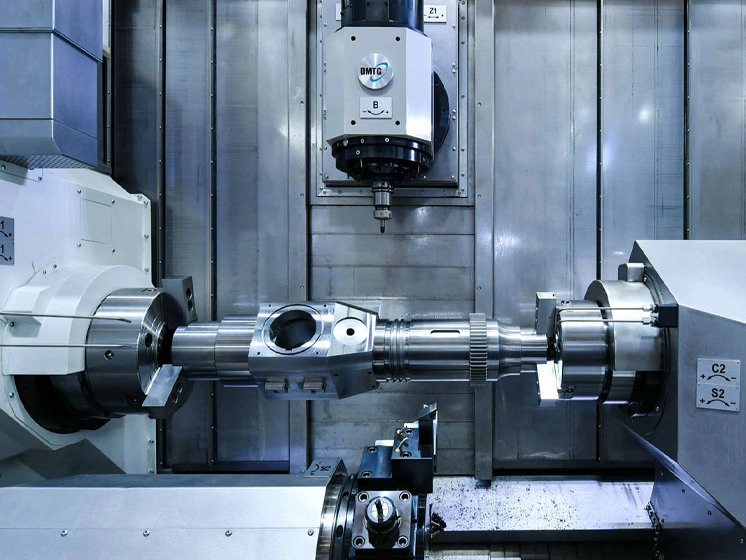

MDH65 Horizontal Machining Center

The MDH65 horizontal machining center is widely suitable for machining box-type parts, housing components, disc-type workpieces, and special-shaped components in industries such as machinery manufacturing. With a single setup, it can automatically complete multi-process machining on four surfaces, including milling, boring, drilling, reaming, and tapping.

| Worktable size (L*W) | 630X630mm |

| No. of Pallet | 2 |

| Table type | IT Opt:BRT |

| Max. table load | 1300kg |

| X/Y/Z axis travel | 1050/900/900mm |

| Max spindle speed | 8000rpm Opt:12000/6000 |

| Spindle motor power | 18.5/22kw |

| Tool magazine capacity | 40 |

| CNC controller | FANUC 31i |

MDH65

The X, Y, and Z-axis ball screws of the machine tool all incorporate advanced hollow cooling technology, which effectively controls thermal deformation during machining operations and enhances the machine’s overall machining accuracy.