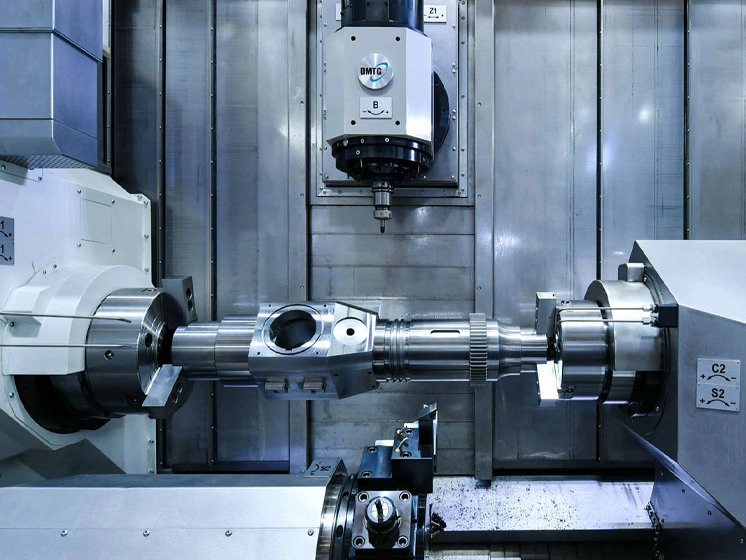

VDLS850 Machining Center

The machine tool features a uniquely robust and durable rigid structure. Through repeated engineering mechanics simulations and calculations, the bed is designed to achieve doubled rigidity with reduced mass, meeting advanced engineering requirements. It is suitable for processing not only plates, discs, housings, and precision parts, but also molds.

| Worktable size(LxW) | 1000X500mm |

| Max.load | 600kg |

| X/Y/Z Axis travel | 860/510/560mm |

| Max. spindle speed | 12000 Direct-driven |

| Tool magazine capacity | 24T/Arm |

| X/Y/Z Axis guide way type | Linear guideway |

| Spindle motor power | 7.5/11kw |

| Spindle taper | No.40(7:24) |

| CNC controller | FANUC,SIEMENS,MITSUBISHI,GSK |

VDLS850

Equipped with an Automatic Tool Changer (ATC), an integrated protective cover, automatic lubrication system, cooling system, and a portable Manual Pulse Generator (MPG), the machine enables multi-process machining—including milling, boring, drilling, reaming, and tapping—in a single setup. It offers high automation, exceptional reliability, user-friendly and ergonomic operation, an aesthetically pleasing appearance, and a high degree of mechatronic integration.