Understanding the difference between a lathe and a milling machine is essential when selecting the right equipment for your machining needs. In this article, we break down the key distinctions between these two versatile machines, highlighting their core functions, common types, and typical industrial applications.

When comparing a lathe vs milling machine, the key difference lies in how each machine removes material. In a lathe, the workpiece rotates while the cutting tool moves linearly, making it ideal for producing cylindrical and rotational parts such as shafts and threaded components. In contrast, a milling machine uses a rotating cutting tool while the workpiece remains fixed, allowing it to machine flat surfaces, slots, contours, and complex geometries.

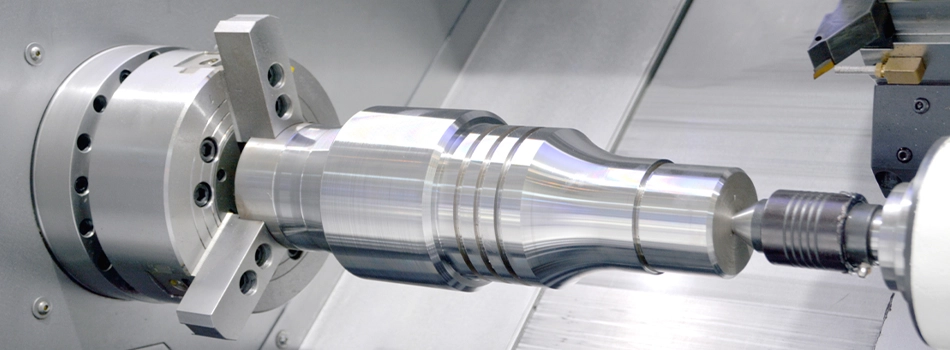

What Is A Lathe Machine?

A lathe is a machine tool designed to shape a rotating workpiece and is often referred to as the “mother of machine tools” due to its fundamental role in machining operations. Its working principle is straightforward: the workpiece is securely clamped on the spindle and rotated at high speed, while a stationary cutting tool moves along a programmed path to remove excess material.This process makes lathes ideal for producing parts with rotational symmetry, such as shafts, discs, wheels, sleeves, threaded components, and other specially contoured cylindrical parts.

Lathes come in various types, each tailored to different machining requirements. The most common types include:

Conventional Lathe (Engine Lathe)

The conventional (engine lathe) is the most basic and widely used type of lathe. It is manually operated and ideal for small production runs and general machining tasks such as turning, drilling, and threading.

Flat Bed CNC Lathe

The flat bed CNC lathe features a horizontal bed structure that offers stable support and easy setup. It is ideal for general turning tasks and cost-effective machining in small to medium production runs.

Slant Bed CNC Lathe

The slant bed CNC lathe features an inclined bed design that improves chip removal, rigidity, and machining stability. It is fully automated and well suited for high-precision, high-efficiency turning of complex parts in medium to large production runs.

Turning Center

A turning center combines the functions of a lathe and a milling machine, offering both turning and milling capabilities in one machine. Turning centers are equipped with a rotating turret or spindle to perform multiple operations without needing to move the workpiece. This multi-functionality reduces setup time and increases overall production efficiency, making it ideal for producing complex parts with multiple features.

Vertical Lathe (Vertical Turning Center)

The vertical lathe, or vertical turning center, is designed with a vertical spindle orientation. This configuration allows for machining larger and heavier workpieces, especially those with a short length and large diameter, such as discs, rings, and flanges. Vertical lathes are commonly used in industries like aerospace and heavy machinery, where heavy-duty and precision machining is required.

Swiss Type Lathe

Swiss-type lathes are specialized machines designed for producing small, complex, and high-precision parts in high volumes. They feature a unique sliding headstock that allows the workpiece to be fed through the tool, which is ideal for machining small, intricate components like pins, screws, and shafts. Swiss-type lathes are particularly popular in the watchmaking, medical, and electronics industries.

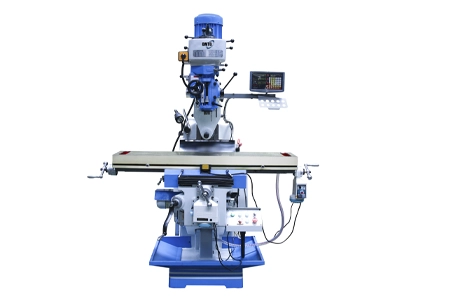

What Is A Milling Machine?

A milling machine is one of the most versatile metal cutting machine tools used in modern manufacturing. Its core working principle is that the cutting tool (the milling cutter) rotates as the primary motion, while the workpiece is securely fixed on the table and moves in a controlled feed motion.By combining the rotation of a multi-edge cutting tool with precise workpiece movement along multiple axes, a milling machine can efficiently produce flat surfaces, slots, contours, curved surfaces, and a wide range of complex geometries.

Vertical Milling Machine

A vertical milling machine features a vertically oriented spindle, making it easy to observe the cutting process and set up the workpiece. It is well suited for machining flat surfaces, slots, and simple contours. Due to its ease of operation and versatility, it is commonly used in tool rooms, workshops, and small to medium production environments.

Horizontal Milling Machine

In a horizontal milling machine, the spindle is mounted horizontally, allowing the cutter to remove material more efficiently during heavy-duty cutting. This design is ideal for machining large surfaces, deep slots, and grooves. Horizontal milling machines are often used in applications that require high material removal rates and strong cutting performance.

CNC Milling Machine

A CNC milling machine is controlled by a computer program, enabling high precision, repeatability, and automation. It can perform complex machining operations with minimal manual intervention. CNC milling machines are widely used in industries such as automotive, aerospace, and mold manufacturing, where accuracy and productivity are critical.

Machining Center

A machining center is an advanced form of CNC milling machine equipped with an automatic tool changer and multiple machining capabilities, such as milling, drilling, tapping, and boring. By completing multiple processes in a single setup, machining centers significantly improve efficiency and reduce production time. They are ideal for machining complex parts with tight tolerances.

Gantry Milling Machine

A gantry milling machine features a bridge-type structure that allows the cutting head to move over large and heavy workpieces. It is designed for machining large-scale components, such as molds, dies, and structural parts. Gantry milling machines are commonly used in heavy industries where high rigidity, stability, and large machining capacity are required.

Lathe vs Milling Machine: Key Differences in Working Principles

Although both lathes and milling machines are essential metalworking tools, they operate on fundamentally different machining principles and are designed for different types of parts.

Working Principle of a Lathe

In a lathe, the workpiece rotates around a central axis while the cutting tool remains stationary or moves linearly along predefined paths. Material is removed as the rotating workpiece comes into contact with the cutting tool.

This rotational machining method makes lathes especially suitable for producing parts with axial symmetry, such as shafts, cylinders, bushings, threads, and other round or tubular components.

Working Principle of a Milling Machine

In contrast, a milling machine operates with a rotating cutting tool, while the workpiece is fixed on the machine table and moves in one or more directions. The rotating multi-edge cutter removes material as the workpiece feeds along different axes.

This approach allows milling machines to produce a wide variety of shapes, including flat surfaces, slots, pockets, contours, curved surfaces, and complex three-dimensional geometries.

Core Differences at a Glance

- Primary Motion

- Lathe: Workpiece rotation

- Milling Machine: Tool rotation

- Typical Part Geometry

- Lathe: Cylindrical and rotational parts

- Milling Machine: Prismatic and complex-shaped parts

- Machining Flexibility

- Lathe: Best for turning operations

- Milling Machine: Ideal for multi-surface and multi-axis machining

Which Machine Should You Choose?

The choice between a lathe and a milling machine depends largely on your part geometry, production volume, and machining complexity. If your components are primarily round and symmetrical, a lathe is usually the most efficient solution. If your parts require flat faces, slots, or complex profiles, a milling machine—or even a machining center—will be the better option.

In many modern workshops, both machines are used together to achieve maximum flexibility and productivity.

Lathe vs Milling Machine in Real-World Applications

In real-world manufacturing, the choice between lathe vs milling machine is largely driven by the specific application and part requirements rather than by machine preference alone. Each machine excels in different production scenarios and often plays a complementary role on the shop floor.

Lathes are commonly used for machining components with rotational symmetry, such as shafts, bushings, and threaded parts. They offer high efficiency and excellent surface finish for turning operations, making them ideal for both small-batch production and high-volume manufacturing of round parts.

Milling machines, on the other hand, are better suited for parts that require flat surfaces, slots, pockets, or complex contours. They are widely used in mold making, structural components, and precision parts where multi-axis movement and geometric flexibility are essential.

In many modern workshops, lathes and milling machines are used together within the same production process. A part may first be turned on a lathe to create its basic cylindrical shape, then transferred to a milling machine or machining center for additional features. This combined approach maximizes efficiency, accuracy, and overall manufacturing flexibility.

Lathe vs Milling Machine in CNC Machining

As automation and precision requirements continue to rise, CNC machines have become a core part of modern manufacturing systems. When evaluating lathe vs milling machine in a CNC environment, the differences are reflected not only in machining methods, but also in production efficiency and operational flexibility.

CNC lathes are specifically designed for stable, high-speed turning processes. They are highly efficient in manufacturing rotational components with tight tolerances, especially in continuous or large-batch production. Advanced configurations such as live tooling, dual spindles, and automated material feeding allow multiple processes to be completed in a single cycle, reducing handling time and improving consistency.

CNC milling machines, including machining centers, are better suited for parts with complex geometries. Their multi-axis movement, combined with automatic tool changing and advanced CNC programming, enables precise machining of pockets, contours, and multi-sided features. This makes them a preferred solution for components that require high design flexibility and detailed surface machining.

From a production planning perspective, CNC lathes are often chosen for efficiency and repeatability, while CNC milling machines offer greater adaptability for complex or customized parts. Selecting the right CNC machine depends on part design, production volume, and long-term manufacturing goals.

Top Lathe Manufacturers

1. DMG MORI (Germany / Japan)

DMG MORI is one of the world’s leading manufacturers of high-end CNC lathes and turning centers. The brand is known for its advanced automation solutions, exceptional precision, and strong presence in aerospace, automotive, and medical industries.

2. MAZAK (Japan)

MAZAK is a globally recognized pioneer in CNC turning technology. Its lathes and turning centers are valued for their reliability, intelligent control systems, and high productivity in large-scale manufacturing environments.

3. OKUMA (Japan)

OKUMA is renowned for its rigid machine structures and in-house control systems. The company’s CNC lathes deliver excellent stability, accuracy, and long-term performance, making them ideal for demanding industrial applications.

4. HAAS Automation (USA)

HAAS Automation is one of the largest CNC machine tool manufacturers in North America. Its CNC lathes are widely used for their cost-effectiveness, ease of operation, and strong global service network.

5. DMTG (Dalian Machine Tool Group, China)

DMTG is one of China’s most influential machine tool manufacturers, offering a wide range of CNC and conventional lathes. The company is known for combining large-scale manufacturing capability with competitive pricing for global markets.

Top Milling Machine Manufacturers

1. SW (Schwäbische Werkzeugmaschinen)

Where unparalleled multi-spindle efficiency meets precision engineering. Ourmodular milling centers redefine high-volume production, turning complexcomponents into simple, automated processes.

2. Mazak

The future of milling intelligence. Our 5-axis and multitasking centers deliver uncompromising precision and flexibility, empowering smart factories with seamless, connected manufacturing solutions.

3. TRUMPF

Revolutionizing material processing with light. Our advanced laser milling and cutting systems create new possibilities in precision manufacturing, setting the standard for next-generation industrial fabrication.

4. Makino

Precision redefined at microscopic levels. Our high-speed milling machines achieve surface finishes and tolerances others can’t reach, mastering the most complex geometries in mold and aerospace manufacturing.

5. DMTG (Genertec Dalian Machine Tool)

Reliable performance, exceptional value. Our comprehensive range of CNC milling machines brings advanced machining capabilities within reach, balancing precision engineering with practical manufacturing needs.

Why Choose Us Instead of Big Brands?

While big brands like DMG MORI, MAZAK, and OKUMA are well-known for their high-end machines, there are several key reasons why choosing us might be the smarter decision for your business:

- Cost-Effective Solutions

We offer high-quality lathes and turning centers at a fraction of the price compared to premium brands. Whether you’re a startup or a small-to-medium-sized enterprise, our machines provide excellent value for your investment without compromising on performance. - Tailored to Your Needs

Unlike mass-market models, we specialize in customizing machines to meet your specific production requirements. From unique workpiece sizes to specialized machining operations, we ensure our lathes work for your unique needs—no compromises. - Local Support & Service

With our strong local presence, you’ll receive quick and reliable customer support. Our technicians are familiar with the local market, offering fast response times, fewer delays, and more personalized service compared to global brands. - Proven Durability

We pride ourselves on the durability and reliability of our machines. Our lathes are built to perform in the most demanding environments, with a focus on long-term stability, minimal maintenance costs, and reduced downtime. - Faster Delivery & Flexible Lead Times

Big brands often have long lead times, especially for customized orders. We offer flexible lead times, ensuring you get the machines you need when you need them, without having to wait for months or deal with long delays. - Building Partnerships, Not Just Transactions

We’re not just a supplier, we’re a long-term partner. We understand the challenges of running a business and are committed to helping you grow. Our team works closely with you, providing ongoing support and expert advice to help you optimize your operations.

In summary, when evaluating lathe vs milling machine, the right choice depends largely on your machining objectives and part requirements. Lathes are best suited for producing round, cylindrical, and rotational components by rotating the workpiece, while milling machines excel at creating flat surfaces, slots, and complex shapes through a rotating cutting tool. Each machine plays a critical role in modern manufacturing, and understanding their differences in working principles, applications, and capabilities is essential for making the right investment.

By clearly defining your production needs, material types, and desired precision, you can select the most suitable solution—whether a lathe, a milling machine, or a combination of both—to maximize efficiency, accuracy, and long-term value.

As a professional lathe supplier, we provide cost-effective alternatives with reliable performance.